How-To: Embroider on Dark Fabrics Part 2

How do you get a design onto dark fabric like jeans or a black sweater? And how do you stitch on a t-shirt? This is Part Two of how to get a design onto dark fabric, and is also the same tutorial for using T-Shirt stabilizer when working on a t-shirt or onesie. If you are working on a plain-weave cotton (like a button-up shirt or a tea-towel) then you want to follow the instructions in Part 1.

- T-Shirt Stabilizer

- sweater, t-shirt or dark jeans

The usual tools for embroidery:

- embroidery needles

- embroidery hoop

- embroidery floss

- optional: glow-in-the-dark thread, tweezers

Let's get started!

Here we have a spongy, knit top. A lightweight sweater. Fabric that is knitted like this (a t-shirt is also a knit fabric) is not the same as woven fabric. You know how when you stretch something that is knitted, the rows become tighter (like those finger-handcuffs that tighten when you try to pull your fingers out)? This type of fabric wants to do the same thing when passing your needle and floss through it. It's stretchy, which makes it incredibly difficult to embroider on. So, how do we stitch the seemingly impossible?

First, let me show you first how not to do it...

WRONG WAY - NO NO

Our good (but delicate) friend, carbon transfer paper, which works great for plain cottons, just won't work for getting a white pattern on bulky, bumpy or soft fabrics (it doesn't work so great on denim either). Why not? Look:

Because the fabric underneath the carbon paper is soft, the pen will just tear through the poor carbon paper.

In order for the carbon to leave a clear imprint on your fabric, you need to be able to apply sufficient pressure. This is why a hard, smooth surface is necessary to have underneath when tracing a design with carbon transfer paper.

So, whaddawe do now?

GET YOU SOME T-SHIRT STABILIZER

There are many, many different types of stabilizers. Some stabilizers are lightweight, some are heavier. Some you tear away, some you leave on. Some stick on like a sticker, some you have to iron on. Some don't adhere to your surface at all and need to be sewn on. Some have to soak in water so they dissolve to be removed. Want me to go on? Hoo boy. Find what works best for you! This (above) is what I use: a medium-weight stabilizer that you iron on and then tear off. No muss, no fuss.

BEFORE WE START: This tutorial is really how to do several things at once. How to stitch on stretchy fabrics, and how to use t-shirt stabilizer as a work-around for getting designs onto dark fabrics. So, this tutorial will work for stitching on white t-shirts and dark jeans.

Step 1: Cut out a piece of stabilizer that fits beyond the size of your hoop.

Even though you're going to iron the stabilizer onto your fabric, a hoop will help limit separation of the stabilizer from your fabric as you stitch, and also limit the amount of stretch to your fabric. Trying to stitch on stretchy fabric without a hoop kinda defeats the purpose of using the stabilizer. They work together as stitching support team, so be sure it's large enough to fit beyond the edges of the hoop.

EXTRA TIP: If you don't like where the stabilizer is, you can peel it up and iron-it back on again. Not, you know, again and again and again, but it can be repositioned once or twice.

WARNING OF WEIRDNESS: if you used an iron-on transfer and then re-iron over it (for re-placement of the stabilizer) the pattern ink will actually fade dramatically when the hot iron goes over it. Remember, you're not re-applying the pattern in this step- just the patterned stabilizer. If this happens, have a pencil handy to trace over some lines that become faint after re-ironing.

Step 3: Enough of that. Put the stabilized fabric on your hoop!

Step 4: Stitch it.

When you stitch, you'll be passing through both layers at the same time: the fabric and the stabilizer. Your fabric shouldn't go up and down like a trampoline. It should remain taut. Keep your hoop tight (but remember to loosen it when not working).

I'll be right back after I stitch this thing...

That was sooo much easier to stitch with stabilizer. So, how do I get this stuff off? Just begin tearing it away?

Not so fast. We don't want to mess up our stitches, mkay? Get ready to de-stabilize. First, peel up all the excess (non-stitched) stabilizer around the design so it's no longer stuck to the fabric before tearing.

Step 7: From the initial tear, continue tearing away the excess stabilizer around the design.

As you were stitching, you were perforating the stabilizer so it should come away pretty easily.

Now we just have the stitched part remaining. How the heck do we remove the rest of this stuff?

This is my secret tip for making this part go faster and easier. Gently pull and stretch the fabric and the stabilizer in different directions. See how it breaks itself up into smaller areas inside each section you stitched? Mmmhm. This will make removing it go much faster, and it's less strain on your stitches than just trying to pull it all up at once.

You can pull longer stitches out of shape when removing the stabilizer, so just go easy on those. But if this happens, no big deal: just pull the floss back through from the opposite side of the fabric to tighten the stitch.

IF USING SCISSORS: Be extra careful when using scissors to remove the stabilizer. It's verrry easy for the point of your pointy scissors to catch and snag your fabric. Tweezers are easierz. Done pickin'?

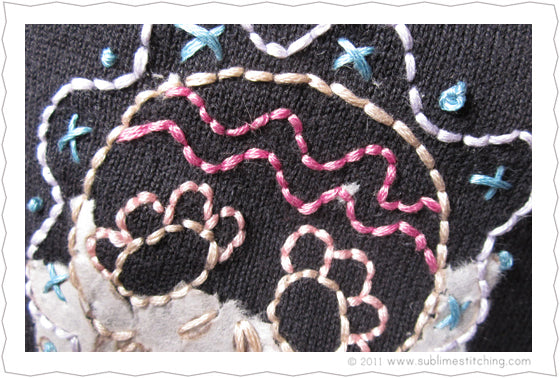

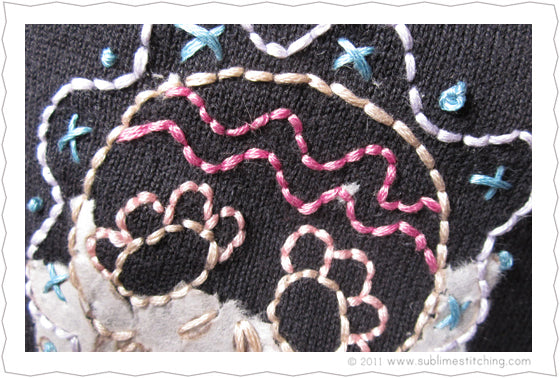

Voilà. You have just stitched a design onto dark, stretchy fabric.

Never again will dark fabrics vex and prevent you from gracing them with your stitches!

Got it? So you don't have to go searching for the links again, here they are:

x - x - x - x - x - x

Text, photos and instructions by Jenny Hart ♥ © 2011 - 2012 Sublime Stitching®. No part of this tutorial may be reproduced in whole or in part without written permission from its author. Man, I hate having to say that. Published on 03/13/11